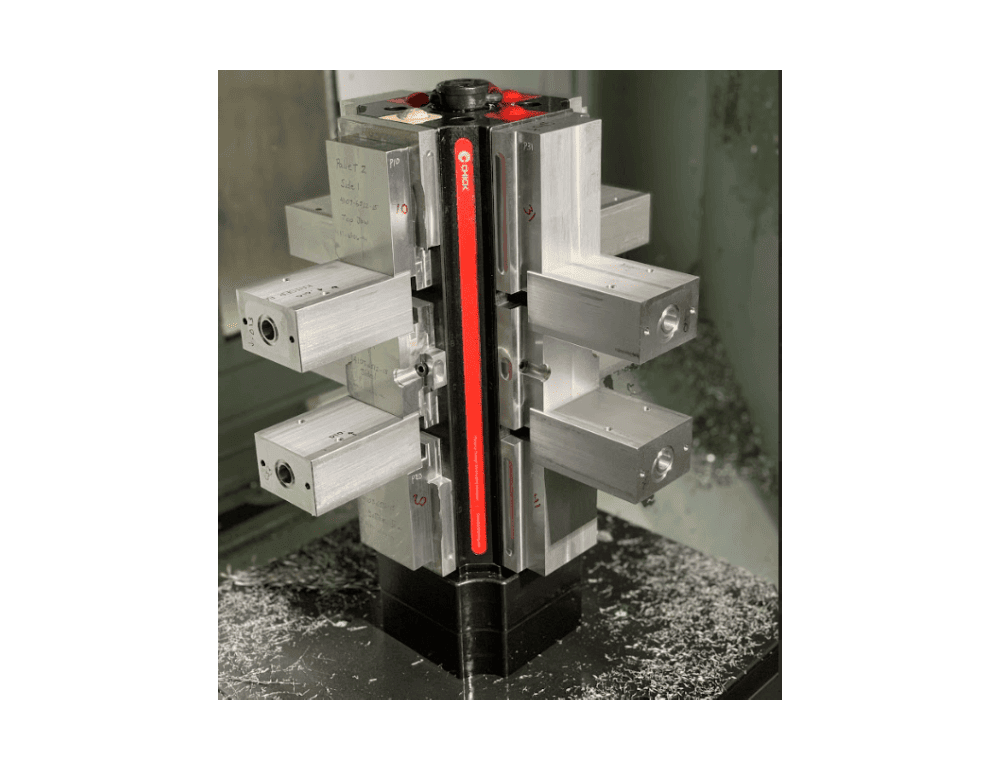

Our diverse range of vertical and horizontal machining centers allow us to handle a broad range of products. From simple, short runs on 3-axis vertical mills, to complex, low to high-volume runs on our 4-axis horizontal machining centers capable of running “lights out”, we have a solution for all your machining needs.

We are pleased to provide milling services for various industry applications, including aerospace & defense, agriculture, construction, electrical power transmission & switching, electronics, energy, fluid & air controls, heavy trucking, medical applications, motion control, plumbing and valve components. We maintain extensive certifications to ensure that we meet and exceed industry standards across the board.

CNC Milling at Hogge Precision

- Up to 4-axis

- Up to 330 tools

- Up to 44” table

- Up to 500 MM Pallets

- Up to 20,000 RPM

- Total tolerances as close as .0005”

We mill a variety of components, such as manifolds, form turning, electrical power transmission & switching, and castings & forgings for a variety of industries:

- Aerospace & Defense

- Construction & Heavy Trucking

- Fluid & Air Controls

- Medical Applications

Advantage of CNC Milling

Quick Turnaround

CNC machining centers are pre-programmed using CAD/CAM software resulting in optimum machining strategies and reduced cost.

Superior Precision

Higher accuracy machine specifications ensure greater precision and reliability.

Variable Production Sizes

Numerous work-holding possibilities to allow for larger scale production with high repeatability.

Material Versatility

CNC machining can be used on a broad range of materials, including difficult-to-machine materials at high speeds.

Enhanced Worker Safety

CNC machining requires less direct human interaction, thereby reducing risk of injury to workers.

Cost-effectiveness

Enhanced speed and unattended CNC machining make it very affordable in comparison with traditional manufacturing methods.