A valve manufacturer was in immediate need of Swiss machining of a stainless steel valve stem. The valve stem was to be used within a valve assembly system used for pressure management. This valve stem needed to be produced on a rush basis. We worked closely with the customer on all aspects of design, tooling was ordered, and production scheduled all within two days.

Within seven working days of the original order, we produced and delivered 11,000 pieces to our client in South Carolina. We made deliveries of 2,000-3,000 per batch to keep the customer’s assembly line up and running, while ensuring they met their deadline. They were thrilled with the product and our turnaround time.

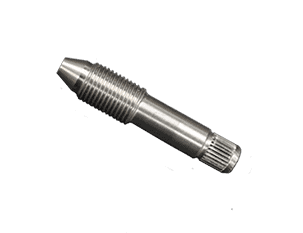

Production processes included rough and finish turning, threading, knurling, grooving, drilling, and boring. The part was made of 303 stainless steel, and measured 1.470” long, with an O.D. of Ø.375”, and tolerances of ±.0005”.

Project Specifications:

With our skilled technicians and advanced equipment, we can meet specific tolerances and specifications to manufacture the best solution for our customers. Below are some of the spec highlights and equipment details from this project:

-

±.0005″ Tightest tolerances

- 0.375″ Outside diameter

- 1.470″ Length

- ISO 9001:2015 Registered

- The component was manufactured using 303 stainless steel.

- The primary piece of equipment used was a Swiss Turning Center.

- To meet the customer deadline, these were machined “lights out” for a quick turnaround.

Machined Components from Hogge Precision

Stainless steel valve stems are one of a myriad of solutions that Hogge Precision can manufacture. Motivated by our vision to be a leading supplier and manufacturer of a diverse range of precision machined components and assemblies, Hogge Precision is ready to manufacture the perfect solution for our customer’s needs.