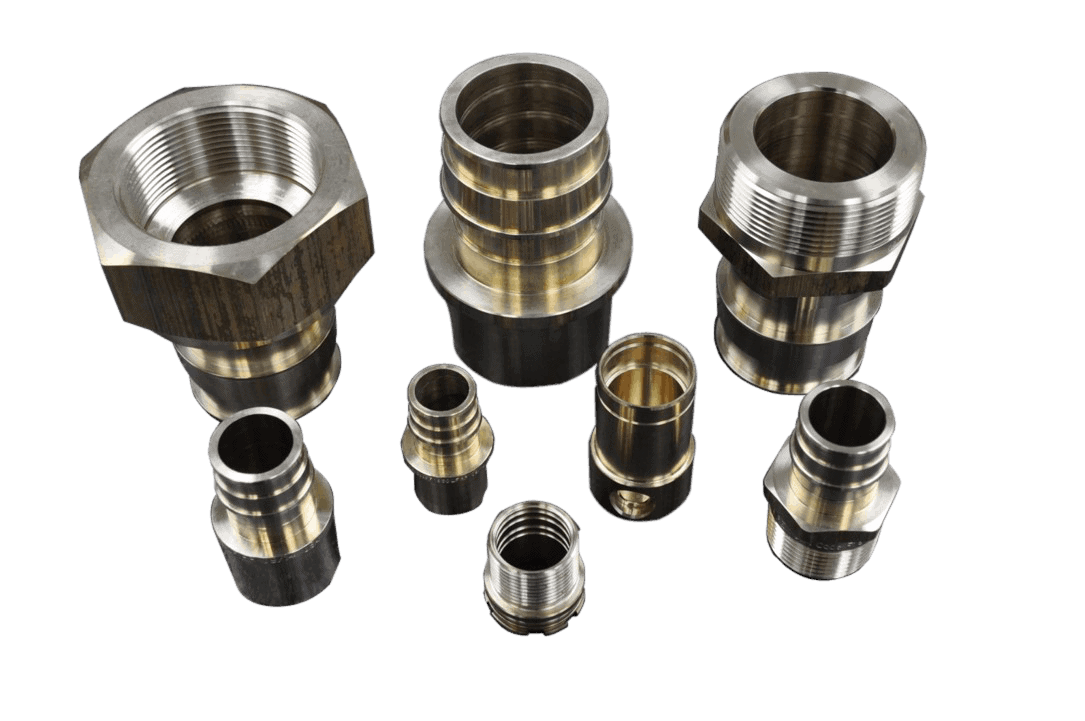

Hogge Precision is your go-to destination for world-class screw machining services. As a leading contract manufacturer, we specialize in screw machining, offering a diverse range of capabilities to meet your exacting precision component needs.

Screw machining generally refers to multi-spindle Swiss-style machines used to manufacture precision parts from bar stock quickly and efficiently and in mid-to-high volumes. We are one of the few remaining precision-machining providers in the Southeast with both single-spindle and multi-spindle machining capabilities.

With screw machining, we can deliver consistent, high-quality parts for your projects, ensuring tight tolerances and fast turnaround times.

- New Britain Cam Driven Screw Machines

- 4 inch max length

- 2.25 inch max diameter

- Tolerances of ±.001 in

- Single-spindle up to 1-5/8″

- Multi-spindle up to 2-1/4”

Our Process: From Bar Stock to Precision Parts

Material Loading

Bar stock is carefully loaded into the material magazine and then fed into the workpiece collet, ready to undergo transformation. Our single-spindle machines can work with bar stock up to 1-5/8″ and our multi-spindle machines go up to 2-1/4”.

Six Stations | Up to 18 Tools

Six stations, one for each spindle, handle up to three machining operations each. Our machines can handle up to 18 different tools in the cut.

Rotation & Repetition

After each operation cycle, the material rotates the workpiece to the next station, and the process repeats. By the time the workpiece has rotated through all six positions, a finished part drops off.

Optimized Cycle Time

Our cycle time is optimized to ensure that the station requiring the longest operation time sets the pace for the entire process.

Materials

At Hogge Precision, we understand that the choice of materials is critical in precision component manufacturing. We offer versatility in material selection, including:

- Brass: Lead-free, known for its corrosion resistance and malleability

- Aluminum: Lightweight and highly corrosion-resistant

- Bronze: Offers excellent wear resistance

- Copper: Conducive to electricity

- Steel: Strong and durable

- Stainless Steel: Combines corrosion resistance with strength

Industries Served

Hogge Precision’s screw machining services serve applications across diverse industries. We specialize in crafting precision components for:

- Aerospace & Defense

- Electrical Power Transmission & Switching

- Fluid & Air Controls

- Medical Applications

- Motion Control

- Plumbing

- Valve Components