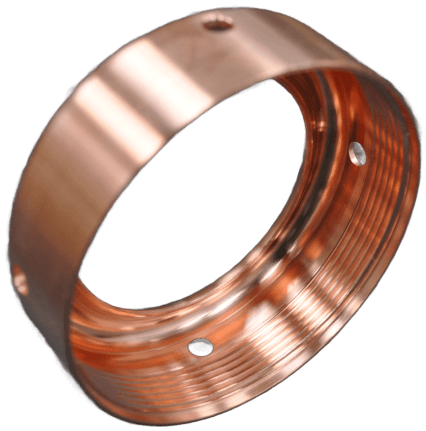

A customer in the power transmission and switching industry came to Hogge Precision in need of a resistor contact. We manufactured the part out of solid 110 copper. This part was completed in one operation using a multi-axis turning center with C & Y axes.

The finished product had an O.D. measurement of 4.000 inches, and was 1.143 inches long. We performed all necessary testing and inspections prior to shipment, then delivered 500 units to the client, who was highly satisfied.

Project Specifications:

With our skilled technicians and advanced equipment, we can meet specific tolerances and specifications to manufacture the best solution for our customers. Below are some of the spec highlights and equipment details from this project:

-

±.0005″ Tolerance threshold

-

.005″ Concentricity

-

5-6 Weeks turnaround time

- ISO 9001:2015 Certification

- The tightest tolerances that can be met are within ±.005″

- The component was manufactured using 110 Solid Copper.

- The primary piece of equipment used was a Single Turret, Twin Spindle Machine with C & Y-Axis.

- The overall part dimensions included an outside diameter of Ø4.000″ and a length of 1.143″. These dimensions were easily replicated and can be produced through our manufacturing with our automation capabilities.

Machined Components from Hogge Precision

Copper resistor contacts are one of a myriad of solutions that Hogge Precision can manufacture. Motivated by our vision to be a leading supplier and manufacturer of a diverse range of precision machined components and assemblies, Hogge Precision is ready to manufacture the perfect solution for our customer’s needs.